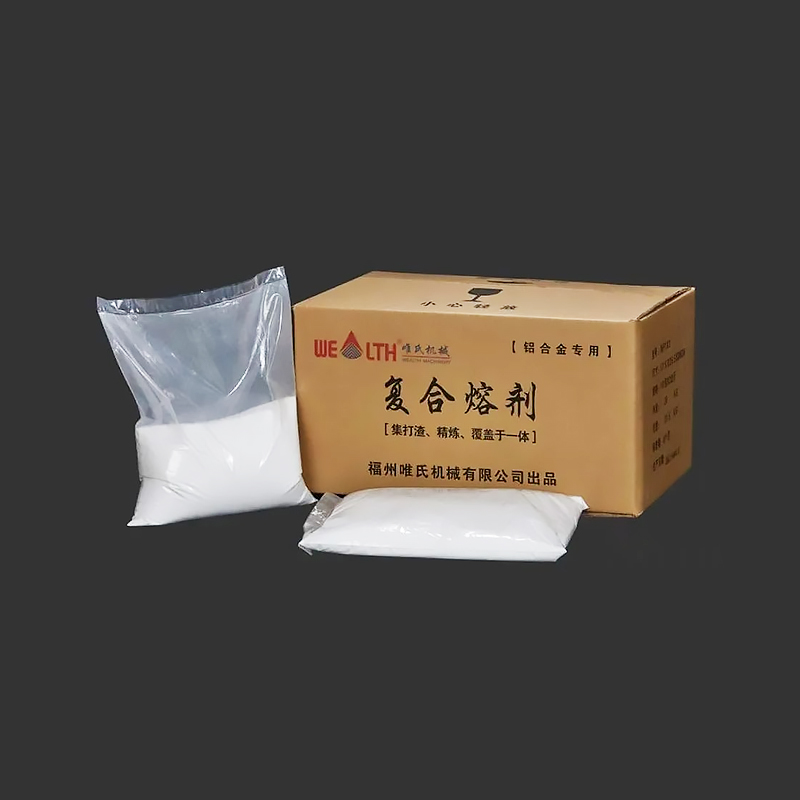

Aluminum alloyflux includes“flux powder"and“multi-functionflux”.The main constituents include sodium salt,potassium salt andfluorine salt.lt is capable of removing the resi-due and gas and p r o v i d i n g t h e coverage.Multi-functionflux(that is four-com-ponent modifier)is also capable of alteration and thinning,and it is the universalflux.Alumi-num alloyflux is smokeless and non-poison-ous,-complies with the national environmen-tal protection requirements,and it is particu-larly suitable for the smelting during the die casting of aluminum alloy crucible.

Methods of application

1.When the smelting temperature of aluminum alloyflux reaches 630-700°C,the aluminum alloyflux in proper amount is spread on the surface of aluminum liquor,and mixed up and down with the strainer then let place for 3-5min,thus the residues can be removed;

2.Theflux addition shall be determined according to the purity of the aluminum liquor,generally 0.2%-0.5%;

3.The ageing of alteration and thinning for compositeflux is 4h.and then it will be degraded.It is recommended to control the ageing of alteration and thinning for the die castings with strict requirements for the structural compactness of aluminum alloy.

Storage notes:

Keep it from moisture and avoid being under pressure in a long time.ln case of any caking,it shall be crushed and then baked beside the furnace before the use,and does not affect the use effect.

Package specification:1kg per small bag,20kg per carton