The punch lubricating drip machine developed by Wei's company is easy to install and use;The drip amount and the spread range of the oil drop can be adjusted to lubricate the punch more effectively,prolong the service life of the punch,save the oil consumption of the punch,and reduce the internal porosity of the casting;Automatic drip,reduce the pollution to the machine and surrounding environment;With independent blowing power,it can clean the residue in the material pipe and improve the inner quality of the casting.

Installation instructions:

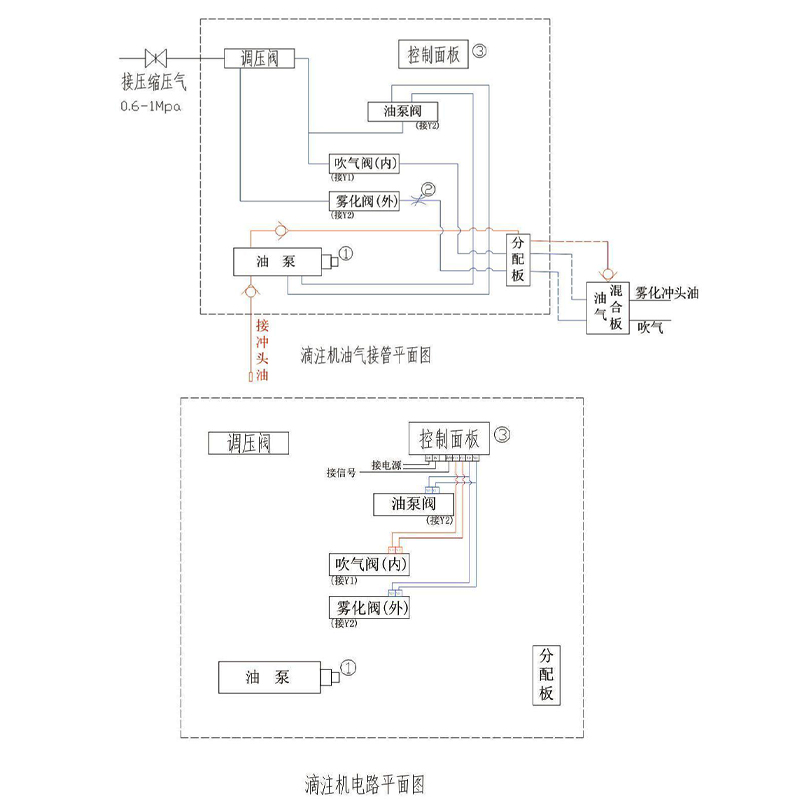

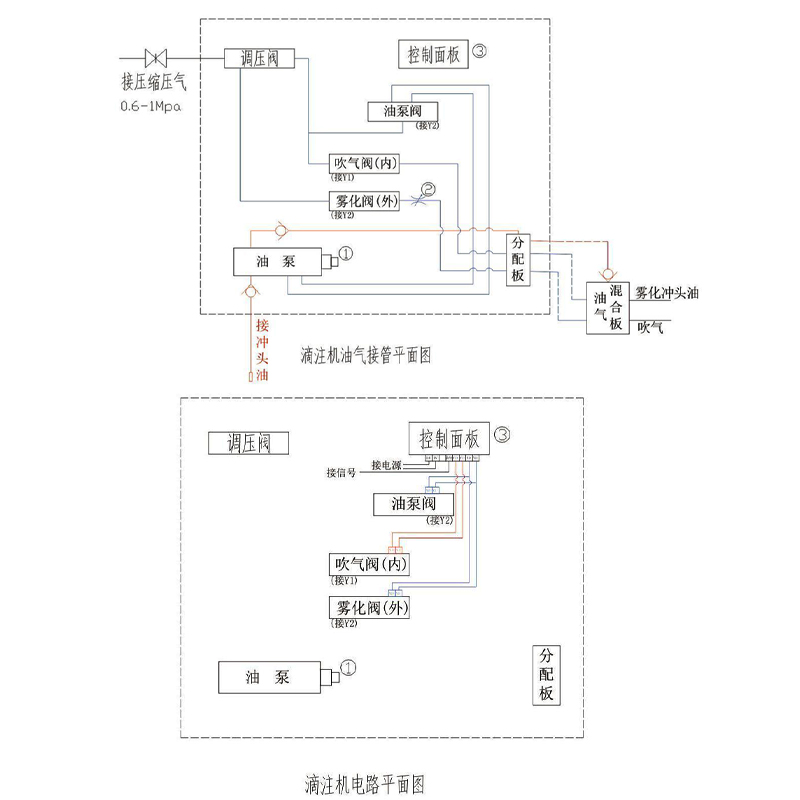

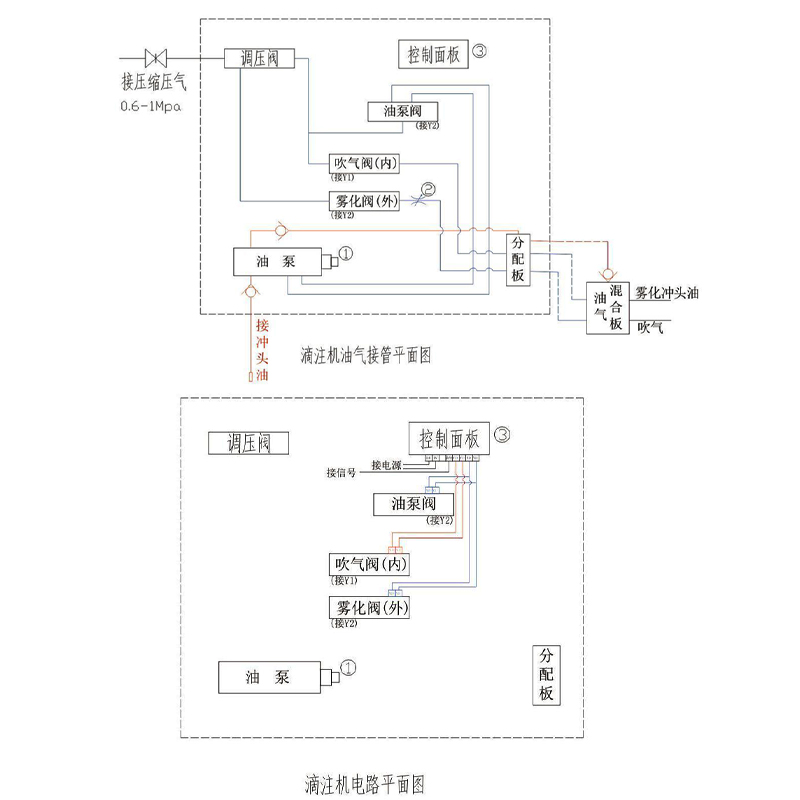

1.Connect the power line(24V,0V)to the DC24V power supply interface of the die casting machine,and connect the signal line to the return signal interface of the injection rod;

2.Insert the siphon with filter into the lubricating oil barrel,the oil level must be higher than half of the filter;

3.The oil-gas mixing plate is fixed on the die casting machine with two M6 screws(hole spacing is 35mm);

4.Adjust the drip pipe and blow pipe(bendable copper pipe)to the proper position of the feeding port.

Instructions for use:

1.By adjusting the hexagonal adjusting rod①on the oil pump to control the amount of fuel injection:clockwise-reduce the amount of fuel injection,counterclockwise-increase the amount of fuel injection;

2.By adjusting the compressed air throttle valve②to adjust the atomization degree of punch oil;

3.Instructions for control panel:

The+and-buttons on the panel are used to set parameters corresponding to each function.

Start delay:the required interval between the receipt of the trigger signal and the start of blowing and oil injection(s);If the signal is taken from the return position signal of the shot rod,the start delay should be set to 0 seconds;Otherwise,the start delay must be synchronized with the ejector rod return in place.

Blowout delay:The working time from the start of blowout to the completion of blowout(s).

Injection times:The injection times in a cycle,can be set 0-9 times of continuous injection.

Working interval:refers to several modes to start a blowing,oil injection action cycle.

Application advantages of drip machine:

1.Effective lubrication,the cost of lubrication is half that of other lubrication methods.

2.Less lubricant,low gas evolution,effectively reduce the inner porosity of casting(especially hydrogen stomata)

3.The residues in the solution cup can be blown away,improve the inner quality of casting.

4.Drop volume can be adjustable,no spot on the casting's surface,improve casting coating performance.

5.Fixed-point and quantitative dripping lubrication,improve the environment around the workshop.

6.Using thefixed-point spray lubrication,uniform coat and effective lubricating,the service life of the plunger tip is multiplied.